Our Story of Nebraska Grape Seed Oil

Nebraska Renewable Energy Systems (NRES) has been tapping into numerous renewable and alternative energy streams in Nebraska for many years. In 2007, NRES first examined grape pomace biomass as a potential oil source for Biofuels production in the rapidly expanding renewable diesel (biodiesel) industry. Difficulties associated with collecting and handling of the wet grape biomass because of poor shelf life, coupled with low oil content saw this work go onto the back burner during the expansion years of biodiesel. Currently, approximately 250 tons of grape seed biomass is created from the rapidly growing Nebraska Wine industry after pressing the grape juice and discarded.

Biodiesel projects came to an abrupt end in 2008 and development in this sector was stagnant for two years as the young industry struggled with their identity based on water use, energy content and human food impact questions raised by the petroleum industry. These years were very slow for NRES and their sister company, Nebraska Screw Press (NSP) who had been part of tremendous progress seen in biodiesel prior to 2008. It was during these years that the answer was to develop process solutions for creating food AND fuel. Our work into human food use oils continued and over the years a simple test was developed for determining the best use of locally squeezed vegetable oils, if it tastes good we eat it!

Renewed efforts into the recycling of grape seed biomass as part of a sustainable viticulture project within the NRES Internship program in 2010/11 saw renewed investments in this project. These efforts confirmed basic processing steps for biomass processing and student efforts calculated energy usages. A critical partner in this effort is Silver Hills Winery in Tekamah, who installed solar energy capacity that would balance the energy used in the grape wine process and earned the distinction of an "energy neutral" wine maker. Silver Hills is continuing clean energy efforts at their Winery with installation of an 85 foot wind turbine in October.

|

|

Crane placing a turbine section at Silver Hills

|

In Fall of 2011 NRES used solar energy to extract the first grape seed oil in Nebraska. Paul Black, University of Nebraska Lincoln provided testing services for fatty acid profiles of several Nebraska Species which helped document this landmark work. The 2012 Season saw renewed efforts to obtain and recycle the grape biomass where almost 3 tons was recovered. In 2013, with Nebraska Environmental Trust and NDEQ grant support, mechanical processing steps and expanded collection systems were funded to greatly expand this recycling opportunity which will see over 20 tons recycled in 2013 with a goal of 50 ton in 2014.

Products obtained through grape biomass recycling process covers the entire value added spectrum from human food to animal feed to energy and composting applications and NRES has used all of them to utilize 100% of the biomass collected while using solar and biofuel energy sources to process it. Seed cleaning steps create several streams that can be used for composting and animal feeds. Our farm raised broilers, hogs and beef eagerly consumed the materials that still contained the valuable seed we could not recover. Leaves, skins, stems, etc are all incorporated into the garden. Seeds are solar dried on hardwood trays and expelled using solar energy to create high value grape seed oil and a meal that can be used for gluten free flour for use in baking or pastas.

|

|

|

|

Grape Seed being separated from skins and stems

|

|

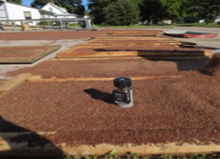

Solar drying of seeds

|

Almost all of the pomace collected in 2013 came from vineyards that use non-persistent ozone in the vineyard in place of chemicals and all biomass separated from the seed was used for feed and/or compost. Grape seed finished broilers, pork and beef was an unexpected benefit of the consistent feed source supplied from our increased collection tonnage. Leaves and skins were incorporated in the garden to increase organic matter.

Livestock feed was fed moist because of short shelf life and was also dried and stored in burlap sacks for use as a Winter feed. Incorporated into feeds about 25%, this reutilization of Winery waste provides a high value product to the farm at a time of year that feed consumption is highest in the Fall. Herds are then reduced going into the Winter to keep Winter feed costs down. Livestock consumption of high anti-oxidant and nutritious grape seed as a finish feed has a triple bottom line and fits well in the Ag cycle.

|

|

|

|

Livestock eagerly consumed materials that still contained seeds we missed

|

|

Any remaining biomass was incorporated into the gardens

|

Once dried, seeds were cleaned and expelled to separate the oil from the grape seed. This secondary cleaning step removes all non-seed materials from the dried seed which provides the cleanest and best oil possible. These cleaning and expelling steps are both labor and energy intensive, but all energy is provided by 100% solar power to run any machinery. Once cleaned the dry grape seed is expelled (or separated) into two products. The first is highly nutritious grape seed oil and the second is the biomass pellets that are created from the remaining non-oil materials of the seed. Because grape seed is very hard and has very low oil content, so special equipment must be used to recover oil.

Our cold pressed grape seed oil is filtered and not processed in any way and can be used for cooking and salads while the remaining pellet can be stone ground to be used as a highly nutritious, gluten free flour substitute or as an animal feed or even as a fuel pellet for biomass heating applications. All of these uses have been demonstrated by NRES over the years and preference is sought for human food uses first.

Nebraska Screw Press is marketing the grape seed oils processed through this project and as a process equipment provider has been involved with initiating this recovery cycle into other parts of the country like Canada, Colorado, New York and Oklahoma. These oils are available as listed below because the grape pomace is hand processed and types separated where possible to allow contrasts between types.

Red Grape Seed Oil

Cold pressed grape seed oil from the numerous red varieties results in a flavorful oil that has a deep green color. These oils come from a variety of red grapes and encompasses about 75% of the recovered pomace materials. Red grape seed oil is processed with hand labor and renewable energy to result in a unique Nebraska product.

White Grape Seed Oil

The sweet white grapes are the first harvested from Nebraska vineyards and are much more difficult to process because the pomace materials are sticky and wet. NSP has developed a number of techniques to recover this oil and it is well worth it. White grape seed oil has a more golden color and lighter flavor than it's red counterpart. As with all of our oils, seeds are solar dried and expelled exclusively using solar power. White grape seed oil represents about 25% of the recovered winery pomace biomass material collected.

|

|

|

|

Cleaning seeds using PV solar

|

|

Expelling seeds into oil and meal pellets

|

Special Reserves

NSP has identified several species of grape that exhibit superior oil content and oil characteristics. These seeds are given additional treatment by hand separation and washing prior to dehydrating. NSP Special Reserve oils in white and red are limited runs and the resulting oils are the best available quality available for these special types. Special reserves represent less than 2% of the grape seed recovered annually and are painstakingly processed to be the best in class.

This advanced work is only being undertaken in the most developed wine regions in the world and Nebraska viticulture finds itself at the cutting edge of this work worldwide not only because of our efforts at NRES but also because of the help and support provided by project partners over the years with special thanks going to Phil and June Simpson of Silver Hills Winery, Paul Black at UNL, Niels Maness of OSU, the Nebraska Environmental Trust and NDEQ who also supported the project with grant funding. Contributing wineries include Silver Hills (Tekamah), Miletta Vista (St. Paul), Soaring Wings (Springfield), James Arthur (Raymond) and Big Cottonwood (Tekamah).

In Conclusion

With this experience base, NSP has partnered with a quality machinery manufacturer to produce pomace processing infrastructure on a far greater scale. These types of opportunities present themselves every year in the form of winery waste that is available for the collection. In that 'waste' stream we can find flours, oil and power polyphenols and color. In time, we will look back on winery waste and laugh at these terrible habits we have become accustomed to. Nebraska Screw Press is leading the way in the development of pomace recycling systems and can provide a custom operation to meet any requirement.

More Information and Downloads

PDFs:

Grape Seed Summary

Freeze and Oven Drying Effects

Grape Processing Flow Chart

Pomace Processing Sheet

NSP Viticulture Brochure

Why Pomace?

Pomace Research

Pomace Project Information

Contact us for further information.